Dare to be different?

BESPOKE 6061-T6 FORGED WHEELS EXCLUSIVELY MADE FOR YOU

Tampa, FL / est. 2019

Render to real life

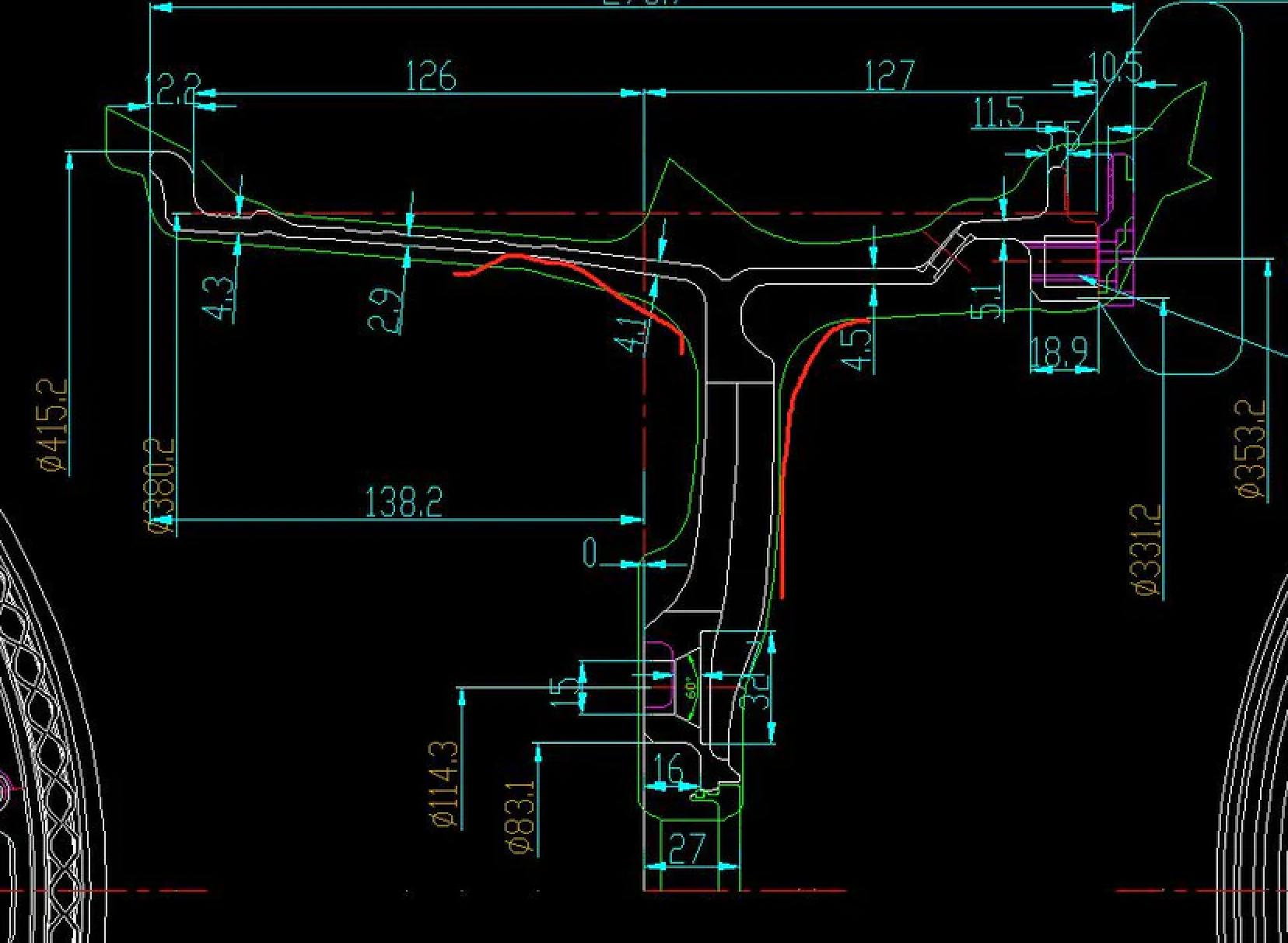

Each set receives a detailed 3D rendering for your approval before production begins.

Before

After

Experience Corsa

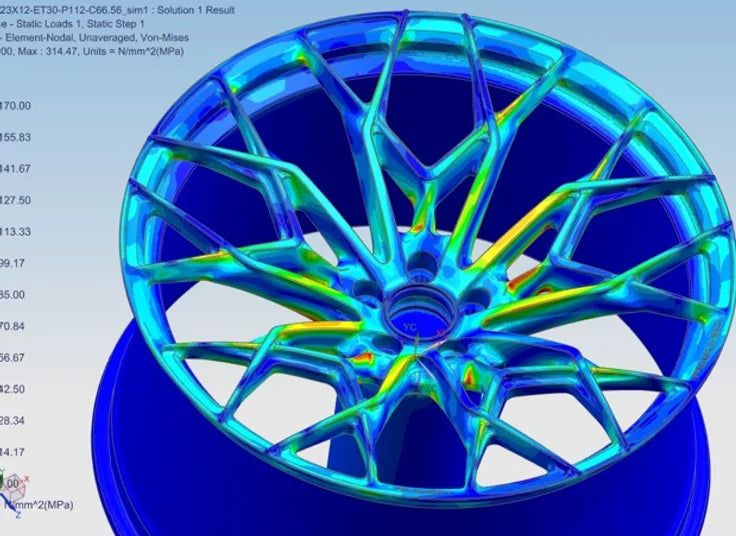

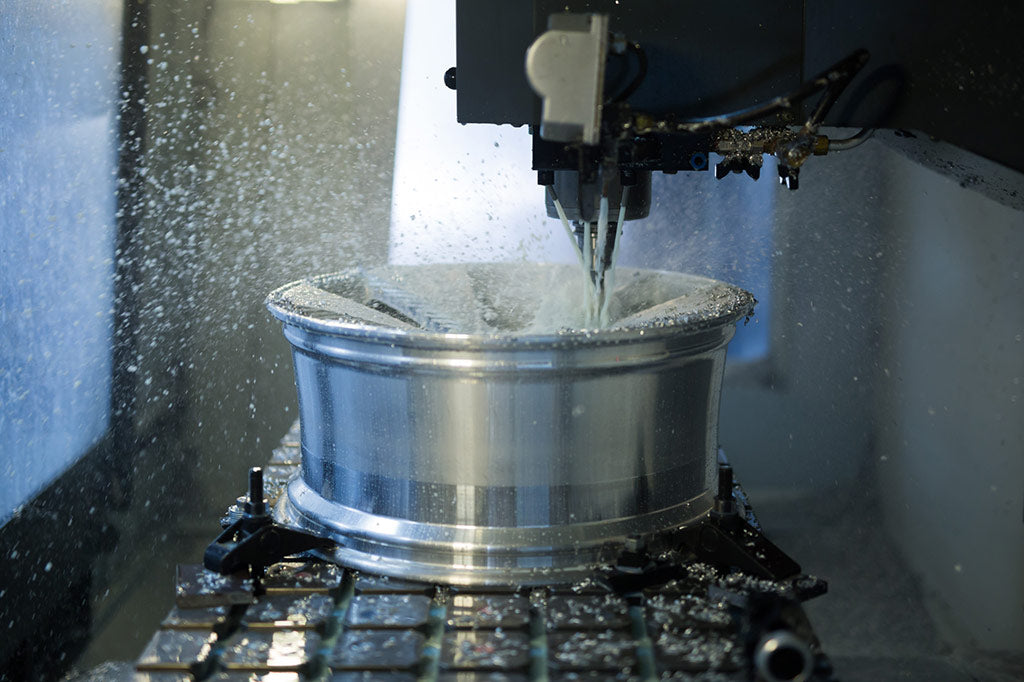

Unmtached Quality. Our bespoke forged wheels are more than just a statement; they are works of art, meticulously crafted to elevate your vehicle to unmatched luxury. Each wheel represents a blend of artistic passion and engineering precision, showcasing our dedication to automotive excellence.

Highest quality powder coats

High-quality powder coating ensures a durable, chip-resistant finish with vibrant colors, protecting our wheels from corrosion and wear for a lasting, premium appearance.

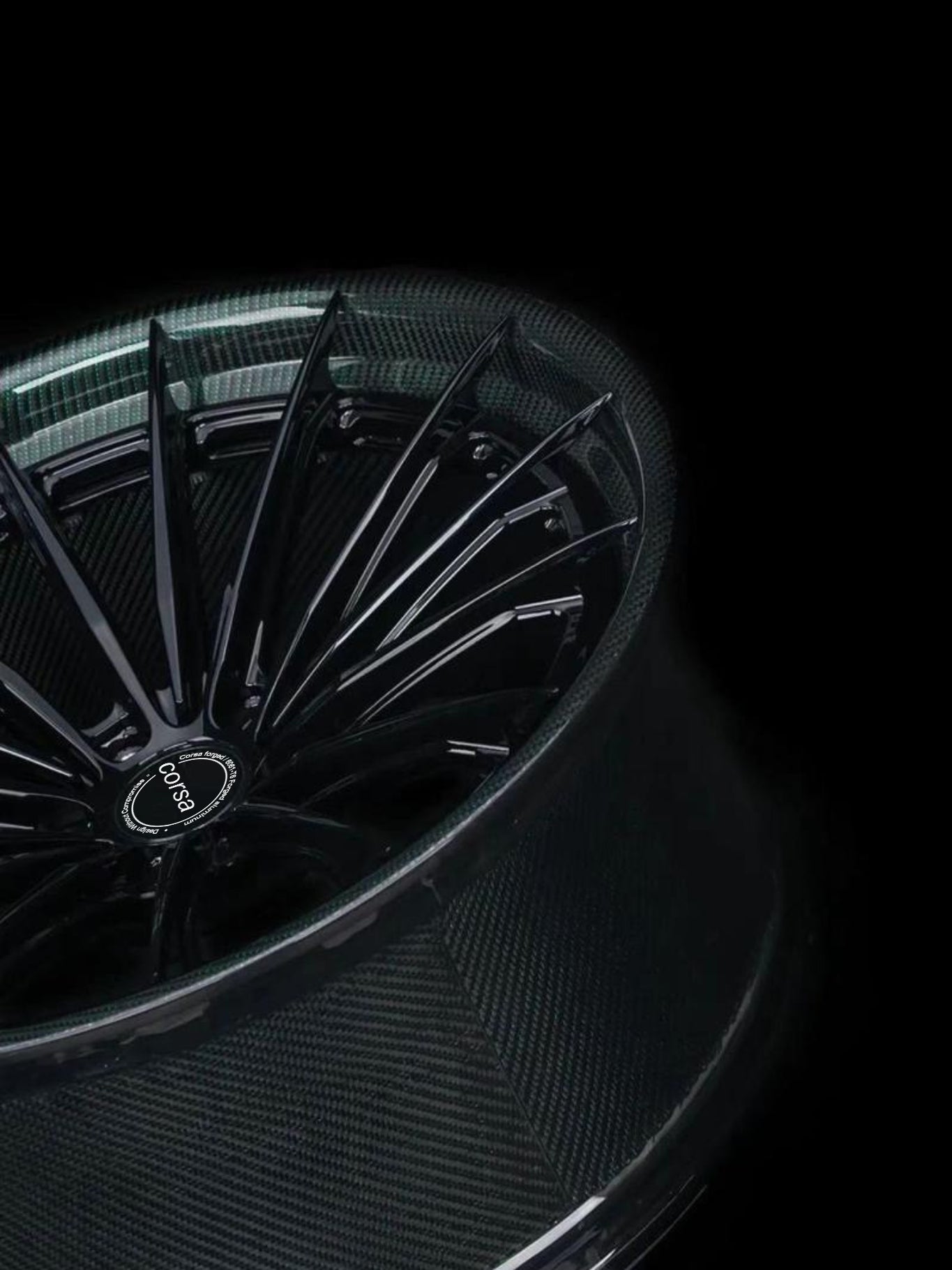

Barrel options

A contemporary step lip option or a classic reverse flat lip options are available to cater to your preferred aesthetic. We even offer full carbon barrels.

Hardware options

Personalize the hardware to suit your preference. Our modular wheels can feature 50/50 exposed, fully exposed, or concealed hardware. You also have the option to choose between Stainless Steel or PVD Black hardware.

For those seeking extreme weight reduction, we offer a titanium hardware upgrade that can trim approximately 1 pound (450 grams) from each wheel, resulting in a total weight savings of 4 pounds (1,800 grams) for a complete set of wheels.

Contact Us

Request a quote

Please include what style, size, and car you're looking for a set of wheels for.

FAQ

Do you ship overseas?

Yes, we offer worldwide shipping at no cost to you!

How long do builds take?

The delivery time varies based on your build. Monoblocks typically take 4-6 weeks, while Duoblocks require 5-7 weeks. Detailed delivery information will be included in your confirmation email.

Any question?

You can contact us through our contact page! We will be happy to assist you.